In today’s fast-paced electronics industry, precision is everything. Laser trimmer technology has revolutionized the way resistors and electronic components are calibrated and optimized. Modern laser trimming machines allow manufacturers to achieve unparalleled accuracy, improving product performance while reducing waste and production time. Whether you are adjusting trimmed resistors or working with complex PCB assemblies, the right resistor trimming machine can make a significant difference in quality and efficiency.

Why Choose a Laser Trimming Machine for Electronics Manufacturing

Traditional mechanical trimming methods often struggle with precision, repeatability, and speed. Laser trimming equipment, on the other hand, provides:

High-precision adjustment of resistor values

Non-contact processing, reducing damage to components

Fast trimming cycles for high-volume production

Compatibility with various types of resistors, including metal film, thick film, and precision resistors

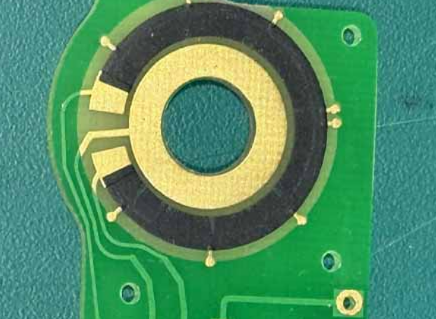

For PCB manufacturers, a pcb resistor trimming process powered by a laser trimming machine ensures consistent electrical performance and longer product lifespan.

Applications of Laser Trimming Machines

Modern laser trimming machines are widely used in:

Precision resistors manufacturing

High-performance electronics, such as sensors and amplifiers

Automotive electronics and industrial control systems

Medical and aerospace electronics, where component accuracy is critical

With advanced laser trimming equipment, manufacturers can adjust resistors on fully assembled boards, optimizing performance without disassembly.

Key Features of Advanced Laser Trimmers

When selecting a resistor trimming machine, consider features such as:

High Accuracy & Repeatability – Essential for micro-ohm adjustments and precision resistor production.

Automated Calibration – Many modern laser trimmers integrate software-controlled trimming and real-time measurement feedback.

Flexible Material Compatibility – Supports a range of resistor types and PCB substrates.

Compact & Efficient Design – Ideal for high-volume production lines or R&D labs.

The combination of advanced optics, precise laser control, and intelligent software makes laser trimming equipment an indispensable tool for modern electronics manufacturers.

Benefits of Using a Laser Trimmer

By integrating a laser trimmer into your production process, businesses can enjoy:

Improved yield and lower defect rates

Faster production cycles for time-sensitive projects

Reduced mechanical stress on components

Ability to produce high-precision trimmed resistors consistently

These advantages help electronics manufacturers stay competitive and meet the demanding standards of modern markets.

Choosing the Right Laser Trimming Equipment

To maximize ROI, consider these factors:

Desired precision and resistor tolerance levels

Production volume and speed requirements

Software automation and measurement integration

Service, maintenance, and supplier support

Investing in a high-quality laser trimming machine ensures your facility stays ahead in both efficiency and product quality.

Conclusion

With electronics moving toward ever higher precision and complexity, laser trimming machines have become essential in modern manufacturing. From pcb resistor trimming to producing top-quality trimmed resistors, the right resistor trimming equipment improves efficiency, reduces errors, and enhances overall product performance.

Contact us today to explore the best laser trimming solutions for your manufacturing needs.